Custom Wine Security Label: Layered Protection for Authenticity and Supply Chain Control

When Wine Value Depends on More Than the Liquid

A wine’s journey—from bottling lines to distributors, from bonded warehouses to final consumers—creates multiple points where authenticity can be compromised.

Counterfeiters refill bottles, replicate labels, and exploit distribution gaps.

A custom wine security label exists to close those gaps by providing visible evidence, traceable identity, and layered anti-counterfeit barriers that hold up under real logistical conditions.

For Huaxin, security labeling is not cosmetic. It is structural protection built for movement, handling, inspection, and verification.

What Wine Producers and Importers Need From Security Labels

Security labels fail when they focus only on “looking secure.”

In real procurement discussions, buyers consistently ask for performance—not appearances:

-

Can the label break or reveal tampering if someone opens the capsule?

-

Can it prevent bottle reuse for counterfeit refilling?

-

Will inspectors be able to verify authenticity in seconds?

-

Can the serial numbers stay readable after shipping, humidity, or cold storage?

-

Is it compatible with automated bottling and labeling machines?

These needs drive the engineering principles behind Huaxin’s custom wine security label systems.

How Custom Wine Security Labels Prevent Fraud

A wine security label must address four major fraud methods:

1️⃣ Duplicate labels

2️⃣ Bottle refilling

3️⃣ Reuse of genuine capsules

4️⃣ Parallel trade or re-exports

Huaxin integrates multiple protective layers designed specifically for wine:

1. Tamper-Evident Behavior

A core requirement is irreversible change when tampering occurs.

Huaxin employs:

-

VOID-transfer neck seals

-

Partial-transfer patterns

-

Destructible materials that fracture under tension

-

Cap-break labels that tear when the cap twists

Once opened, it cannot be concealed.

This eliminates the largest counterfeit method—bottle reuse.

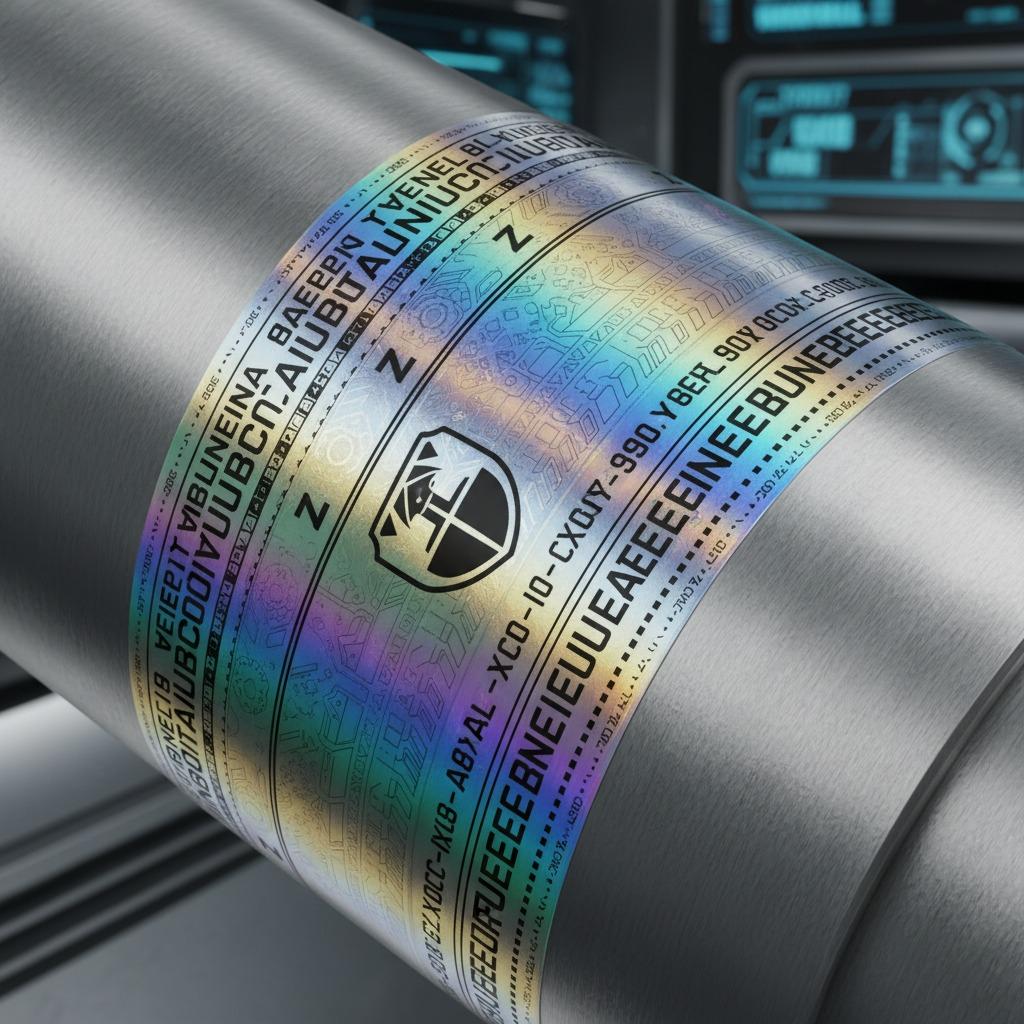

2. Multi-Level Anti-Counterfeit Features

Security must be readable at different depths:

-

Overt (visible to consumers): hologram, color-shifting ink, guilloche patterns

-

Covert (visible under tools): UV inks, microtext, nano-lines

-

Forensic (high-risk markets): coded markers or layered fibers

-

Digital layers: serialization, QR-linked authenticity pages

These layers combine to create a label that is practically impossible to replicate convincingly.

3. Serialized Identity for Distribution Control

Serialization connects every bottle to its origin, batch, and intended market.

Huaxin supports:

-

Per-bottle serial codes

-

Date/batch identifiers

-

Region-specific marks

-

Optional digital traceability

This enables:

-

Distributors to verify legitimacy

-

Authorities to inspect more efficiently

-

Brands to detect market diversion or parallel exports

For premium wines, serialization is now considered essential, not optional.

4. Adhesive Systems Built for Glass and Capsules

A curved glass surface is one of the hardest materials for adhesion.

Humidity, cooling, transportation vibration, and foil capsule texture all affect performance.

Huaxin’s adhesive engineering ensures:

-

Strong bonding during distribution

-

Clear evidence of removal attempts

-

Stability from cold chain storage to high-temperature transport

-

Clean residue pattern visibility when tampered

This is where generic labels fail most frequently.

Where Custom Wine Security Labels Are Commonly Used

Applications extend across the entire wine economy:

-

Premium and collectible wines

-

Export and bonded warehouse shipments

-

National excise control programs

-

Online retail and last-mile delivery

-

Hospitality and on-premise distribution

-

High-risk regions with active counterfeit markets

Every bottle that moves through multiple hands benefits from a layer of engineered verification.

How Huaxin Builds Custom Wine Security Labels

Huaxin’s production system merges secure printing, adhesive technology, and data management into a unified workflow.

Manufacturing Steps

-

Fraud-risk assessment based on wine type and markets

-

Security artwork development (overt + covert features)

-

Material and adhesive calibration for bottle surfaces

-

Variable data printing for serialization

-

Environmental stress testing (humidity, cold chain, abrasion)

-

Roll or sheet configuration for automated application lines

ISO 14298-compliant secure printing controls ensure that every batch behaves consistently across thousands of units.

Why Brands Select Huaxin

Huaxin provides more than labels—it provides reliable, verifiable security architecture for the wine industry.

Key strengths include:

-

Secure printing environment (ISO 14298)

-

Custom holographic and multi-layer optical features

-

Adhesives engineered for tamper evidence

-

High-speed, high-accuracy serialization

-

OEM customization for brand and regulatory needs

-

Proven export capability for cross-border wine distribution

A McKinsey 2024 Beverage Fraud Review identifies wine as one of the most counterfeited alcohol categories globally—a trend that reinforces the value of engineered protection.

FAQ — What Buyers Need to Clarify Before Ordering

Can we integrate hologram + serialization + tamper evidence in one label?

Yes. Multi-layer integration is available in one unified design.

Will labels survive refrigerated transport?

Huaxin tests adhesives and inks under cold-chain conditions.

Can the label prevent capsule refitting after refilling?

Tamper-evident fracture designs ensure irreversible damage.

Can we print region-specific marks for parallel trade control?

Yes. Variable data and regional coding are fully supported.

A Label That Protects More Than the Package

A custom wine security label is not a branding accessory—it is a safeguard for authenticity, pricing integrity, and distributor confidence.

With Huaxin, wineries and importers gain a security solution engineered for how wine actually moves through global supply chains—not how it sits on a design file.

To request OEM samples or discuss wine security solutions, visit the

Huaxin homepage or contact us here.