Tamper Evident Wine Seal Factory: Engineered Protection for Bottles, Capsules, and Global Distribution

A Wine Seal Must Do More Than Tear—It Must Tell the Truth

In the wine industry, the most serious fraud does not happen on paper.

It happens at the capsule—where counterfeiters refill bottles, reseal closures, and move fakes through supply chains with alarming ease.

A tamper-evident wine seal is the first and last line of defense.

Not because it looks secure, but because it behaves securely:

it breaks, stretches, separates, or reveals hidden patterns in ways no counterfeiter can reverse.

This functional behavior—not the artwork—is what global wine producers and importers rely on.

What Wine Brands Actually Need From a Tamper-Evident Seal

Every procurement conversation for wine seals centers around real operational risks, not aesthetics:

-

“Can the seal break in a way that cannot be repaired or reattached?”

-

“Will it reveal tampering even if only a small area is lifted?”

-

“Can it prevent capsule removal or refitting?”

-

“Does it adhere consistently to glass and irregular capsule surfaces?”

-

“Will it survive humid storage, temperature swings, and shipping vibration?”

Huaxin designs seals based on these real expectations—not theoretical assumptions.

The Engineering Behind an Effective Wine Seal

A tamper-evident wine seal is a technical product built from micro-layer materials, engineered adhesive systems, and controlled fracture logic.

1. Engineered Fracture Patterns

The seal must break in a controlled, irreversible way.

Huaxin creates fracture behaviors such as:

-

Destructible paper that tears in micro-fibers

-

PET with pre-scored break zones

-

VOID-transfer patterns that expose hidden text

-

Partial-transfer layers ideal for coated capsules

Once tampered, the damage is visible from any angle.

2. Adhesives Calibrated for Capsules and Glass

Wine capsules are complex: aluminum, tin, PVC, or polymer blends.

Their curvature and surface coatings make adhesion challenging.

Huaxin formulates adhesives that:

-

Bond permanently to curved surfaces

-

Hold under refrigeration moisture

-

Retain tack through long-distance shipping

-

Reveal clear signs if someone lifts or stretches the seal

This stability is what protects the bottle through its entire journey.

3. Anti-Refill Protection

A tamper-evident wine seal is not only about detecting opening—it is about stopping reuse.

Huaxin’s seals prevent common fraud methods by:

-

Fracturing when capsules twist or deform

-

Leaving residue that exposes removal

-

Splitting across different layers when lifted

-

Combining seal + capsule behavior for structural defense

The result is a seal that cannot be removed and reapplied without obvious destruction.

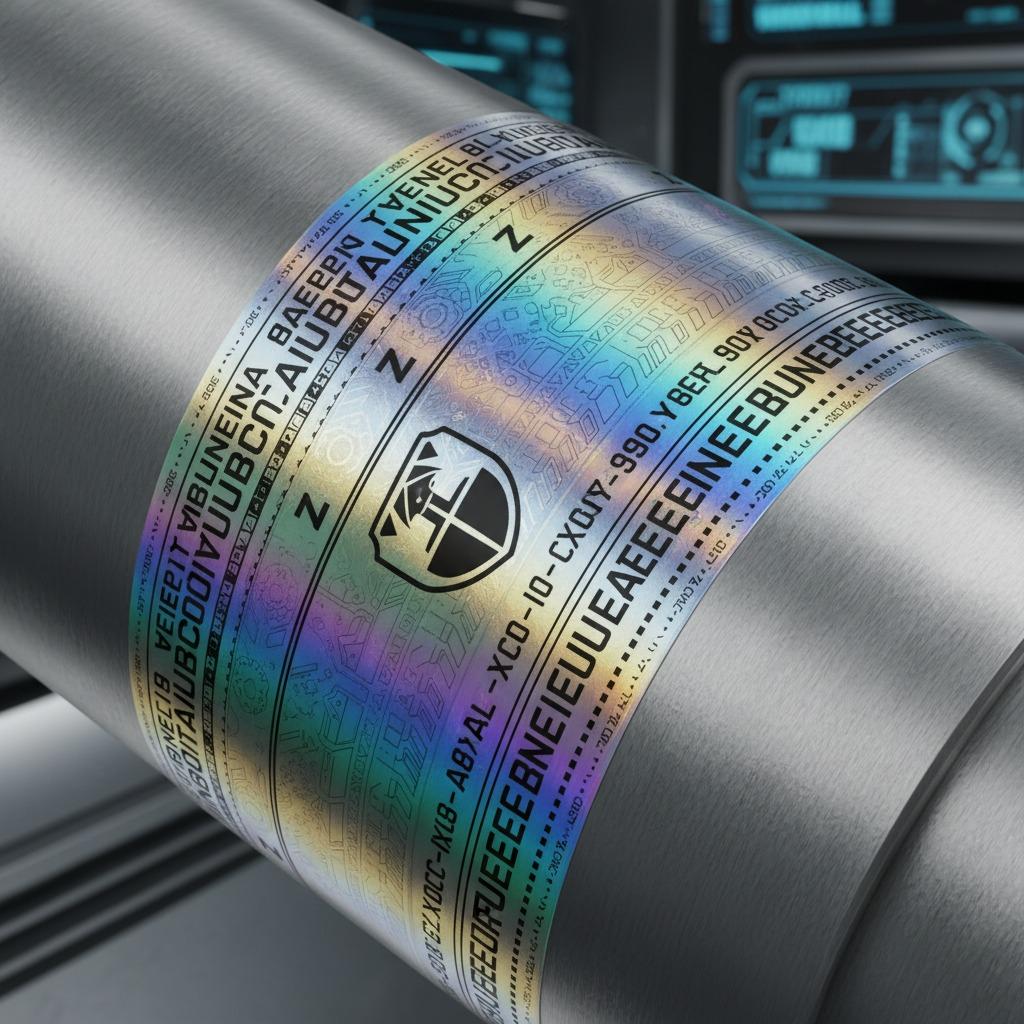

4. Security Printing for Instant Verification

Wine inspectors and distributors need fast, reliable visual checks.

Huaxin integrates:

-

Holographic optics

-

UV fluorescent inks

-

Microtext

-

Guilloche line patterns

-

Serialized QR or batch codes

These help detect imitation labels at a glance or with simple inspection tools.

Application Scenarios Across the Wine Supply Chain

Tamper-evident seals are used at every point where authenticity is at risk:

-

Premium and collectible wines vulnerable to refilling

-

Export shipments requiring inspection-ready protection

-

Domestic wines passing excise or customs checkpoints

-

E-commerce packaging where consumers expect visible security

-

Hotel, restaurant, and bar supply chains

-

Markets with active counterfeit activity or parallel trade

A seal is not decoration; it is operational insurance.

How Huaxin Manufactures High-Performance Wine Seals

As a dedicated tamper evident wine seal factory, Huaxin combines secure printing technology with material science to engineer reliable behaviors at scale.

Production Workflow

-

Material evaluation for capsule type and neck geometry

-

Tamper-behavior design (fracture, transfer, or destructible logic)

-

Adhesive formulation matched to climate, handling, and storage

-

Security printing using holographic or covert inks

-

Serialization for batch control and market traceability

-

Environmental testing (humidity, cold-chain, abrasion, transport stress)

-

Roll/sheet conversion for automated bottling application

ISO 14298 secure-printing compliance ensures consistency across all batches.

Why Leading Producers Select Huaxin

Huaxin’s advantage lies in technical precision rather than surface design.

Key strengths include:

-

Reliable tamper-evident behavior engineered by fracture design

-

Adhesives that bond to curved, coated, or composite capsule surfaces

-

Integrated hologram, microtext, and serialization

-

OEM production flexibility for wineries and importers

-

Long export experience for regulated alcohol markets

According to McKinsey’s 2024 Beverage Fraud Analysis, tamper-evident seals reduce bottle-refill fraud by up to 45%, making them the most cost-effective anti-counterfeit measure for wine brands.

FAQ — Procurement Questions That Matter

Can one seal work for all capsule materials?

Different materials require different adhesives. Huaxin calibrates per project.

Can seals integrate hologram + VOID + serial code?

Yes. Multi-layer integration is common for premium wines.

Will the seal break reliably under cold storage?

Yes. Break zones and adhesives are tested under low temperatures.

Can seals support automated application?

Huaxin offers roll formats compatible with bottling-line applicators.

A Seal That Protects the Bottle—and the Brand

A tamper-evident wine seal is not simply a security layer.

It is a guarantee that every bottle reaching a distributor, retailer, or consumer is authentic, unopened, and trustworthy.

With Huaxin, wine brands gain seals engineered for real handling, real risks, and real distribution—not theoretical security.

To request samples or discuss OEM wine seal solutions, visit the Huaxin homepage or contact us here.