Wine Anti-Counterfeit Label: Secure Identification That Protects Value Across the Supply Chain

When Wine Becomes a Target, Labels Become a Line of Defense

The wine industry carries a specific vulnerability: the product is valuable, portable, easy to refill, and traded across borders.

This creates the perfect environment for counterfeiters—fake labels, reused bottles, diluted wine, and unauthorized re-exports.

A wine anti-counterfeit label is created to stop exactly these threats.

Not by looking pretty, but by making authenticity verifiable and tampering impossible to hide.

For producers, importers, and premium wineries, this label becomes as critical as the bottle itself.

The Real Problems Wineries and Importers Face

Through Huaxin’s work with global brands,几乎所有采购者在初次沟通时都会提出相同的痛点:

1. Refilled bottles entering the market

Counterfeiters buy empty genuine bottles, refill them, and reseal them.

Without a tamper-evident mechanism, the fake looks real.

2. Duplicate labels on unauthorized shipments

A simple QR code is not enough—if it can be scanned, it can be copied.

3. Parallel trade and grey-market circulation

Wines intended for one market end up being resold elsewhere.

Brands need labels that link a bottle to its intended region.

4. Lack of reliable tracking during distribution

Distributors want proof of legitimacy, not assumptions.

5. Regulatory pressure for traceability

More governments require serialization or digital verification in alcohol safety programs.

A wine anti-counterfeit label must solve all these issues—not just one.

What Makes a Wine Anti-Counterfeit Label Effective

Based on real procurement requirements, four technical capabilities determine success.

1. Irreversible Tamper Evidence

If a bottle can be opened without leaving traces, the entire system collapses.

Huaxin uses tamper-evident systems such as:

-

VOID-transfer wine seals

-

Partial-transfer neck seals

-

Destructible paper or film labels

-

Cap-break labels that fracture when twisted

Every option ensures:

Once opened, it can’t go back to “new.”

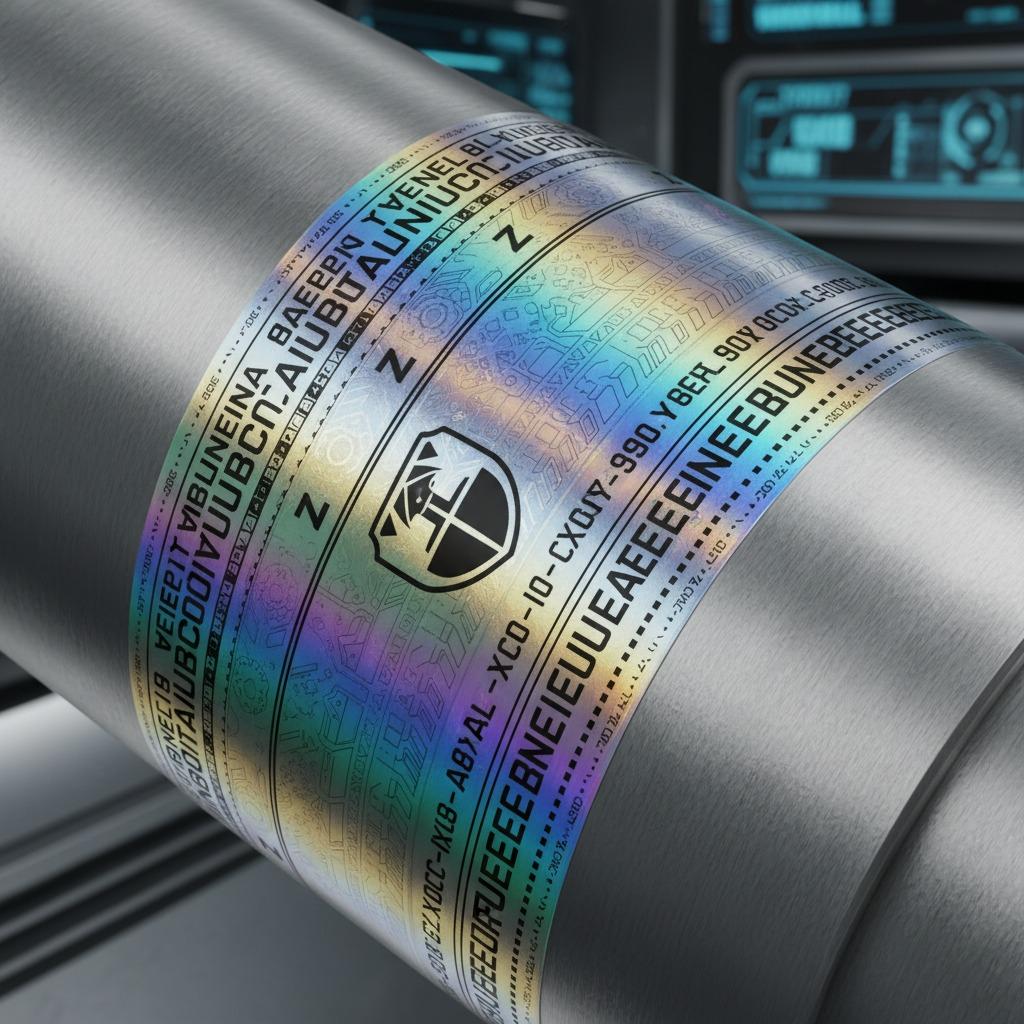

2. Multi-Layer Visual and Covert Security

A single hologram is no longer enough.

Huaxin constructs wine anti-counterfeit labels with stacked layers such as:

-

Holographic optics

-

Microtext or nano-lines

-

UV fluorescent patterns

-

Secure guilloche backgrounds

-

Complex line artwork

-

Optical variable ink (OVI)

-

Optional QR or NFC authentication

These features make duplication extremely difficult—even with high-end printing equipment.

3. Serialization That Links Every Bottle to Its Origin

A wine anti-counterfeit label is not complete without unique identity.

Huaxin provides:

-

Per-bottle serial numbers

-

Batch codes

-

Market-specific markings

-

Optional digital verification platforms

This allows:

-

Importers to confirm authenticity

-

Distributors to track shipments

-

Authorities to verify excise compliance

-

Brands to identify parallel-trade flows

Serialization is not decoration—it is control.

4. Adhesive Behavior Matched to Bottle Materials

The neck of a wine bottle contains three difficult surfaces:

-

Curved glass

-

Metal/foil caps

-

Lacquered coatings

Huaxin calibrates adhesives that ensure:

-

Permanent adhesion

-

No clean removal

-

Clear evidence of tampering

-

Stability under refrigeration, humidity, and transportation vibration

This is where many generic labels fail.

Where Wine Anti-Counterfeit Labels Are Used

These labels are not only for ultra-premium wines.

They protect value across:

-

Premium and collectible wines (risk of refilling is highest)

-

Imported wines for bonded warehouses

-

E-commerce shipments (customer trust)

-

Hotel, restaurant, and bar supply chains

-

Duty-free and travel retail

-

Regional market control for distributors

Wherever wine moves, fraud finds opportunity—and labels become accountability markers.

How Huaxin Designs Anti-Counterfeit Labels for Wine Brands

Huaxin combines secure printing, adhesive engineering, and serialization into one integrated system.

Standard production steps include:

-

Fraud-risk assessment based on wine category and target markets

-

Security layout design (covert + overt features)

-

Adhesive and material selection for bottle type

-

Variable data printing for serials or batch codes

-

Environmental durability testing (cold storage, moisture, abrasion)

-

Roll-format preparation for automated application

This workflow ensures that the final label protects the bottle before, during, and after distribution.

Why Leading Wine Brands Choose Huaxin

Huaxin is not simply a sticker printer—

it operates as a secure-label engineering partner built around high-value consumables like wine.

Capabilities include:

-

ISO 14298 secure printing management

-

Multi-layer high-security printing technologies

-

Tamper-evident adhesives for glass and caps

-

High-speed serialization and batch tracking

-

OEM customization for brand identity and regional rules

-

Proven export experience

A McKinsey 2024 Food & Beverage Fraud Insight reports that wine remains among the top 5 most counterfeited alcohol categories worldwide, underscoring the critical need for robust labeling.

FAQ — Questions Wine Producers Ask Before Ordering

Q1: Can we combine hologram + serialization + tamper-evident in one label?

Yes. Huaxin specializes in multi-functional label integration.

Q2: Will the label survive cold-chain transportation?

Tamper-evident adhesives are tested under low-temperature storage conditions.

Q3: Can labels prevent refilling?

Yes. Cap-break and VOID-transfer systems make clean resealing impossible.

Q4: Can we track bottles by region?

Yes. Serialization or QR coding can embed region-specific data.

Protecting Wine Value Starts With One Label

A powerful wine anti-counterfeit label is not a luxury—it’s a necessary shield against fraud, parallel trade, and supply-chain manipulation.

With Huaxin, wineries and importers gain a security label engineered to behave correctly under real distribution stress—not just look convincing on a design board.

To request OEM samples or discuss anti-counterfeit labeling options, visit

the Huaxin homepage or contact us here.