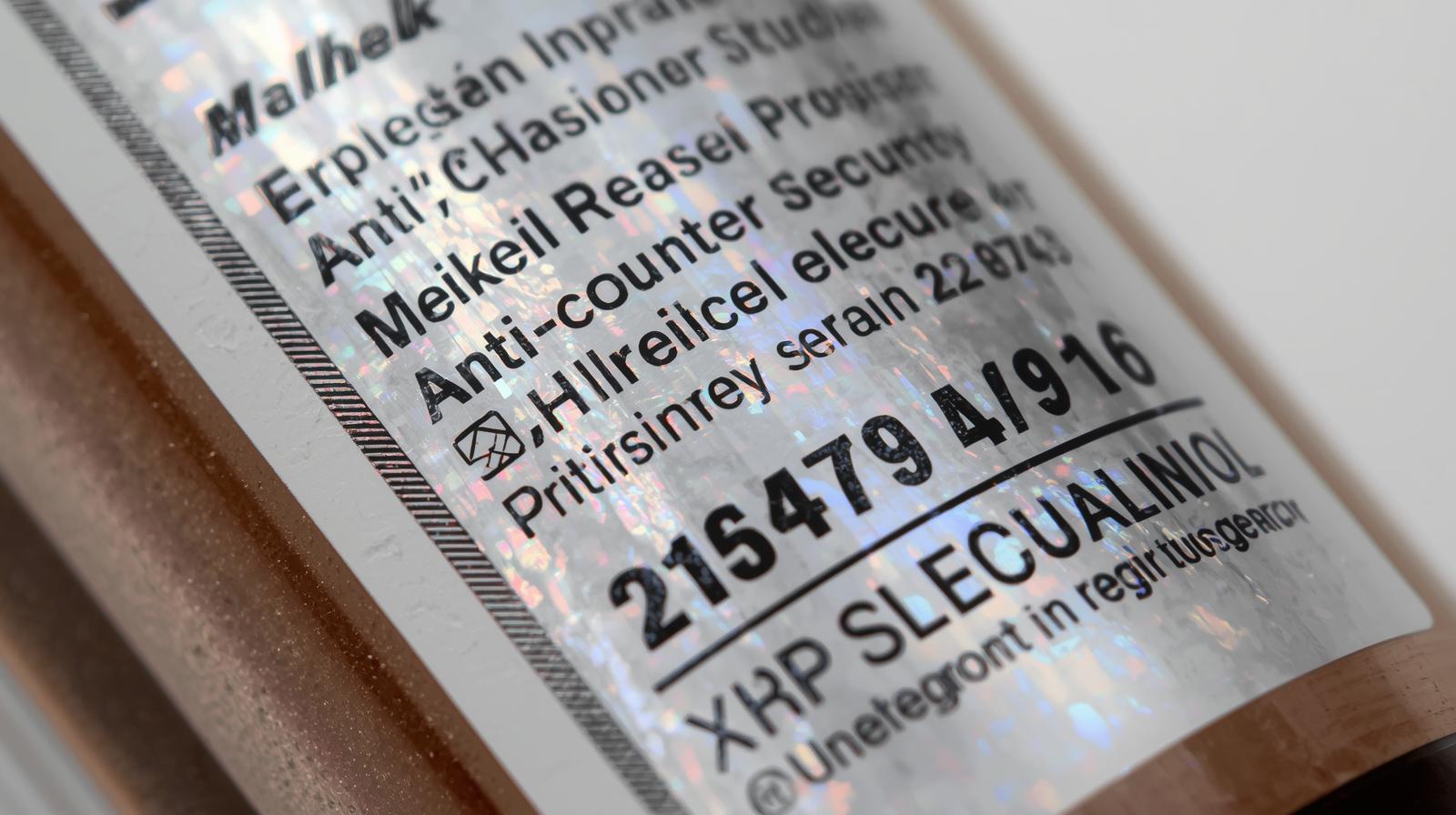

Anti Counterfeit Label Printing That Still Works After Transport, Storage, and Handling

Counterfeiting Often Happens After the Factory—Not Inside It

Most brands design anti-counterfeit labels with one assumption:

that the label will be inspected in near-perfect condition.

Reality is different.

Products are stacked, rubbed, frozen, heated, compressed, and handled by multiple parties before reaching the market.

If an anti-counterfeit label loses adhesion, cracks unintentionally, fades, or partially detaches during this process, it creates uncertainty—and counterfeiters exploit that uncertainty immediately.

This is why anti counterfeit label printing must be engineered for logistics stress, not just visual security.

What Brands Actually Lose When Labels Fail in Transit

When a label degrades before inspection, the consequences are not minor.

-

Inspectors hesitate to validate authenticity

-

Distributors question shipment integrity

-

Consumers lose confidence

-

Counterfeiters gain plausible deniability

A label that fails during normal handling becomes a liability.

A label that remains stable—but fails only when tampered with—becomes a control point.

Huaxin designs anti-counterfeit labels around this distinction.

The Core Problem: Confusing Durability With Security

Many anti-counterfeit labels fail because durability and tamper behavior are treated as the same thing.

They are not.

A label must:

-

Remain intact during legitimate transport and storage

-

Fail decisively when someone tries to remove or manipulate it

Achieving both requires controlled material behavior, not generic label stock.

How Huaxin Engineers Anti-Counterfeit Labels for Logistics Stress

1. Material Stability Under Environmental Variation

During transport and storage, labels face:

-

Temperature swings

-

Humidity changes

-

Friction and compression

-

Long dwell times in warehouses

Huaxin selects and tests substrates that:

-

Maintain structural integrity under heat and cold

-

Resist curling, cracking, or delamination

-

Preserve printed security features over time

Durability is verified before security features are applied—not after.

2. Adhesive Systems That Know When Not to Fail

One of the most common mistakes in anti-counterfeit label printing is using adhesives that are either too aggressive or too weak.

Huaxin calibrates adhesives to:

-

Hold firmly during transport and handling

-

Resist accidental lifting at edges

-

Remain stable under humidity and condensation

-

Activate tamper behavior only when deliberate removal is attempted

This separation between logistics stability and tamper activation is critical.

3. Tamper Mechanisms Designed for Intentional Action

Anti-counterfeit labels must fail on purpose, not by accident.

Huaxin engineers tamper behavior using:

-

VOID transfer layers that activate only under peel force

-

Destructible materials that fracture under removal, not vibration

-

Partial-transfer systems that respond to separation, not abrasion

This ensures that damage signals tampering—not poor handling.

4. Print Integrity That Survives Handling

Security printing is meaningless if it fades, smears, or becomes unreadable before inspection.

Huaxin uses printing systems that ensure:

-

Fine-line patterns remain sharp after friction

-

Microtext remains legible under magnification

-

UV and covert inks retain response after aging

-

Serialization remains readable and scannable

Authentication depends on clarity, not decoration.

Why Generic Labels Fail After Distribution

Standard labels often pass factory checks but fail in the field.

| Performance Area | Generic Label | Huaxin Anti-Counterfeit Label |

|---|---|---|

| Transport abrasion | Inconsistent | Controlled |

| Adhesion stability | Variable | Calibrated |

| Accidental edge lift | Common | Minimized |

| Tamper signal clarity | Ambiguous | Immediate |

| Inspection confidence | Low | High |

Counterfeiters exploit ambiguity.

Huaxin designs labels to remove it.

Application Scenarios Where Durability Matters Most

Logistics-resistant anti-counterfeit labels are critical in:

-

Alcohol and beverage distribution

-

Pharmaceuticals and healthcare products

-

Electronics and components

-

Cosmetics and personal care

-

Exported goods under customs inspection

-

Multi-warehouse or multi-distributor supply chains

In these environments, labels are tested long before they are checked.

How Huaxin Validates Real-World Performance

As a secure printing manufacturer, Huaxin treats durability as part of security.

Validation Process

-

Environmental stress testing (temperature, humidity)

-

Handling simulation (friction, stacking, vibration)

-

Adhesive performance evaluation

-

Controlled tamper testing

-

Serialization readability checks

-

Batch consistency verification

All production follows ISO 14298 secure printing management systems, ensuring repeatable performance—not one-off results.

Why Brands Choose Huaxin for Anti-Counterfeit Label Printing

Huaxin’s advantage is not more features—it is controlled behavior.

Key strengths include:

-

Security labels that survive logistics without false tamper signals

-

Tamper mechanisms that activate only under deliberate interference

-

Stable serialization across long distribution cycles

-

Adhesives engineered for real surfaces and conditions

-

OEM manufacturing discipline for global supply chains

Industry analysis, including McKinsey’s 2024 Global Illicit Trade Report, highlights how ambiguity in packaging security increases counterfeit risk—especially after distribution.

FAQ — Practical Questions Buyers Ask

Will durable labels still show clear tamper evidence?

Yes. Durability protects against handling, not removal.

Can labels handle cold storage or hot transport?

Materials and adhesives are selected and tested for these conditions.

Will serialization remain scannable after transport?

Yes. Print systems are chosen for long-term readability.

Can labels be applied by automated lines?

Yes. Roll formats are compatible with industrial applicators.

Anti-Counterfeit Protection Must Survive the Journey

An anti-counterfeit label that fails before inspection creates doubt.

One that survives transport, storage, and handling—and fails only under tampering—creates trust.

With Huaxin, anti counterfeit label printing is engineered for real logistics conditions, real inspection behavior, and real counterfeit risk.

To discuss durable anti-counterfeit label solutions or request technical samples, visit the

Huaxin homepage or contact us here.