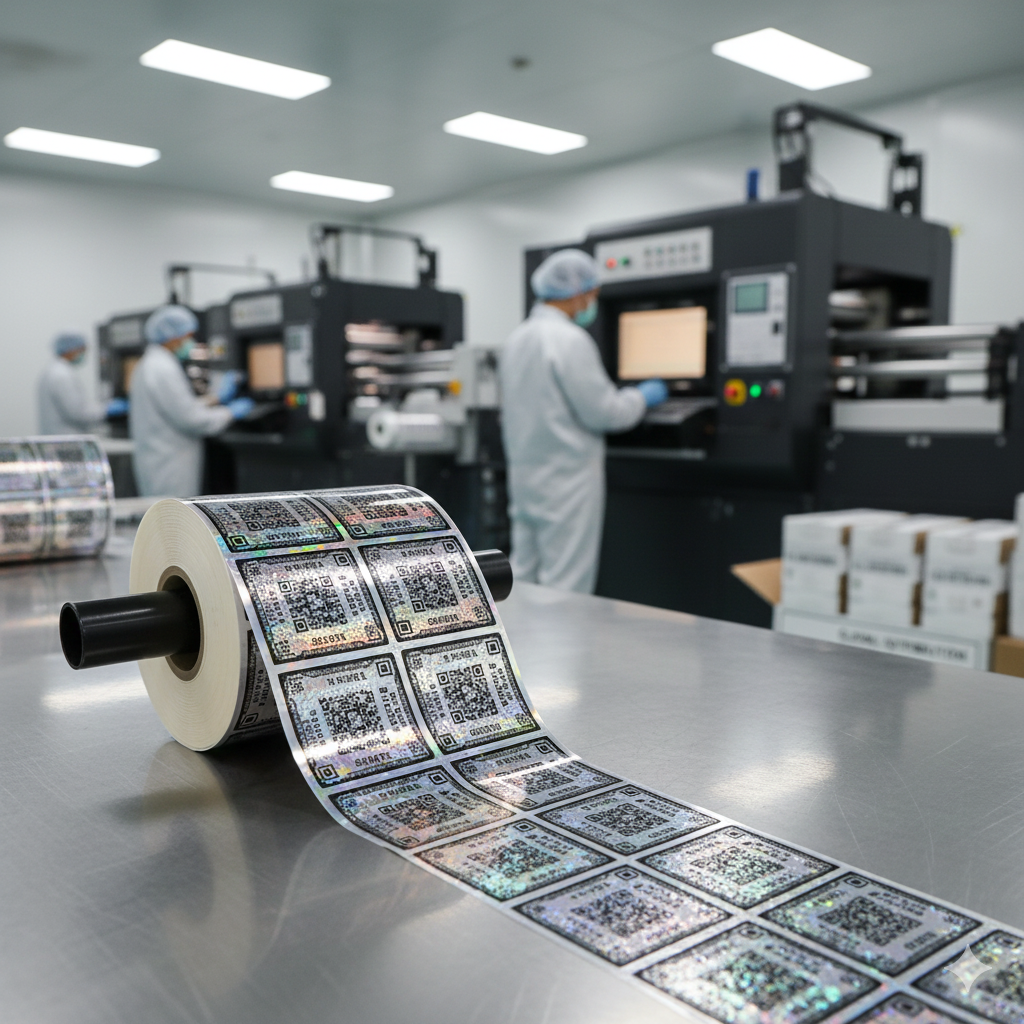

Food-Safe Security Labels for Products with Short Shelf Life

Short Shelf Life Leaves No Time for Security Errors

When a food product expires in days or weeks, security decisions must happen immediately—or not at all.

There is no time for secondary inspections.

No patience for ambiguous labels.

No tolerance for security systems that require training or explanation.

For short shelf life products, food-safe security labels must deliver instant clarity, clean tamper evidence, and zero interference with food safety or packaging speed.

Why Short Shelf Life Products Face Unique Security Risks

Short shelf life products are often assumed to be “low risk.” In practice, they are not.

They are vulnerable because they combine:

-

Rapid turnover

-

Frequent handling

-

Visual-only inspection

-

Reusable or resealable packaging formats

-

Limited post-market traceability

Counterfeiters exploit the fact that by the time an issue is discovered, the product has already been sold—or consumed.

What Food-Safe Security Labels Must Achieve in Short Shelf Life Cycles

Immediate Tamper Recognition Without Interpretation

In short shelf life distribution, security labels must work at a glance.

Huaxin designs tamper behavior that is:

-

Binary: untouched or clearly compromised

-

Overt: visible VOID patterns, layer separation, seal breakage

-

Irreversible: no cosmetic recovery after opening

There is no room for “maybe” in products that expire quickly.

Materials Selected for Safety, Not Just Durability

Short shelf life does not reduce food safety requirements. It increases scrutiny.

Huaxin selects materials based on:

-

Suitability for indirect food contact

-

Low migration ink systems

-

Films that remain stable under refrigeration

-

Substrates that do not shed fibers near openings

Security labels must never introduce contamination risk—even when applied close to lids or seals.

Authentication That Matches the Speed of Expiration

When product life is short, authentication must be immediate and decisive.

Huaxin integrates Barcode Anti-Counterfeiting Technology to enable fast verification during spot checks, distribution handovers, or recall situations.

This allows short-life products to be authenticated without delaying movement or requiring additional tools.

Adhesive and Structural Design for Fast Expiry Packaging

Adhesives behave differently under short shelf life conditions because packaging is often chilled, condensed, and handled repeatedly.

Huaxin engineers adhesives that:

-

Bond instantly during high-speed application

-

Resist edge lift from moisture and condensation

-

Maintain adhesion through refrigeration cycles

-

Trigger tamper evidence only during intentional removal

Structurally, labels are designed to match real packaging formats—cups, trays, pouches, and bottles—rather than idealized flat surfaces.

How Barcode-Based Control Reduces Risk Before Expiry

In short shelf life scenarios, there is no second chance to verify authenticity.

Barcode Anti-Counterfeiting Technology allows brands to:

-

Confirm authenticity at random control points

-

Detect duplicated or reused packaging early

-

Identify abnormal distribution patterns

-

Act before the product expires

Security must operate faster than the shelf life itself.

Typical Failure Points in Short Shelf Life Food Labeling

| Risk Area | Generic Labels | Huaxin Food-Safe Security Labels |

|---|---|---|

| Tamper visibility | Subtle or disputed | Immediate and obvious |

| Food safety assurance | Unclear | Material-controlled |

| Adhesion under condensation | Edge lift | Stable bond |

| Verification speed | Too slow | Barcode-based |

| Reuse prevention | Weak | Structurally enforced |

How Huaxin Designs for Short Shelf Life Food Products

Huaxin approaches short shelf life labeling as a time-critical system, not a decorative feature.

Design and Production Workflow

-

Shelf life duration assessment

-

Packaging opening and handling analysis

-

Food-safe substrate and adhesive selection

-

Tamper logic and seal structure design

-

Integration of Barcode Anti-Counterfeiting Technology

-

Condensation and cold storage testing

-

Batch traceability under ISO 14298 secure printing management systems

Each step is optimized for speed, clarity, and compliance.

Short Shelf Life Categories That Require Specialized Security

These food products benefit most from this approach:

-

Fresh dairy and chilled foods

-

Ready-to-eat meals

-

Fresh beverages and juices

-

Prepared salads and desserts

-

Nutritional foods with rapid turnover

In these categories, delays equal losses.

Why Barcode-Based Security Fits Short Shelf Life Economics

Short shelf life products cannot absorb high operational complexity.

By using Barcode Anti-Counterfeiting Technology, brands gain:

-

Low-cost scalability

-

Compatibility with existing scanners

-

Minimal training requirements

-

Measurable reduction in reuse and diversion

Security becomes operational, not theoretical.

FAQ — Questions Commonly Asked by Food Brands

Will these labels slow down packaging lines?

No. All designs are compatible with automated, high-speed application.

Are the materials suitable for food packaging compliance?

Yes. Materials and inks are selected for indirect food contact environments.

Is barcode-based verification realistic for short shelf life products?

Yes. Barcode Anti-Counterfeiting Technology aligns with existing food logistics workflows and delivers immediate results.

When Shelf Life Is Short, Security Must Be Decisive

Short shelf life products do not allow time for uncertainty.

Security must be visible, fast, and compliant from the first touchpoint.

With Huaxin, food-safe security labels are engineered around real expiration cycles—combining controlled tamper behavior, compliant materials, and barcode-based authentication that works before the clock runs out.

Learn more at the

Huaxin homepage or contact our team directly via

Contact-us.