When Inspection Is Limited, Labels Must Speak for Themselves

In many global markets, inspection is not systematic.

Customs officers are understaffed. Retail checks are inconsistent. Field inspectors lack tools, time, or training.

In these environments, authenticity decisions are made in seconds—often based on what is immediately visible.

If a security label requires explanation, scanning equipment, or expert interpretation, it fails in practice.

This is why security labels for weak inspection infrastructure must be engineered for instant clarity, not layered complexity that no one has time to interpret.

Why Conventional Security Labels Fail in Low-Enforcement Markets

Many anti-counterfeit labels are designed for ideal conditions: trained inspectors, UV lamps, databases, and controlled checkpoints.

In weak-infrastructure markets, those assumptions collapse.

Common failure modes include:

-

Covert features no one checks

-

QR systems that rely on unstable connectivity

-

Subtle tamper signs easily ignored

-

Labels damaged during transport and dismissed as “normal wear”

Counterfeiters thrive where enforcement depends on interpretation instead of certainty.

What Security Labels Must Do When Inspection Is Minimal

1. Make Tampering Impossible to Ignore

In low-inspection environments, subtlety is a weakness.

Huaxin designs security labels with tamper behavior that is:

-

Highly visible: large VOID text, bold break patterns

-

Immediate: damage appears at first interference

-

Irreversible: no way to restore original appearance

If a container is opened or a label lifted, the evidence is unmistakable—even to untrained eyes.

2. Eliminate Dependence on Tools and Databases

When inspectors lack UV lights or scanners, security must be self-explanatory.

Huaxin prioritizes:

-

Overt visual security over hidden-only features

-

Clear before/after tamper contrast

-

Human-readable logic instead of system-dependent validation

Digital layers can exist—but physical security must stand alone.

3. Control Label Behavior Under Rough Handling

In weak-infrastructure markets, logistics conditions are often uncontrolled.

Security labels must withstand:

-

Manual handling

-

Repacking and relabeling attempts

-

Heat, humidity, and dust

-

Repeated transfers between distributors

Huaxin engineers materials and adhesives that remain stable during normal abuse—but fail decisively when tampered with.

4. Prevent Reuse and Label Transfer

One of the most common counterfeit tactics in these markets is label recycling.

Huaxin prevents reuse by ensuring:

-

Labels fragment or transfer on removal

-

Residue patterns remain on original containers

-

Tamper marks cannot be concealed or trimmed away

A reused label should never look “acceptable.”

Why High-Tech Security Often Underperforms in Weak Markets

Ironically, more technology often means less effectiveness.

| Security Approach | Outcome in Weak Markets |

|---|---|

| QR-only validation | Rarely checked |

| Covert-only features | Ignored |

| Subtle tamper signs | Disputed |

| Tool-dependent checks | Infeasible |

| Clear visual failure | Effective |

In these environments, clarity beats complexity.

Products Most Affected by Weak Inspection Conditions

Security labels designed for weak enforcement are critical in:

-

Alcohol and spirits

-

Pharmaceuticals and supplements

-

Cosmetics and personal care

-

Agricultural chemicals

-

Imported consumer goods

-

Grey-market-prone products

In these categories, labels often serve as the primary line of defense.

How Huaxin Designs Security Labels for Weak Infrastructure Markets

Huaxin approaches these markets with a simple rule:

If authenticity cannot be explained in one sentence, the design is wrong.

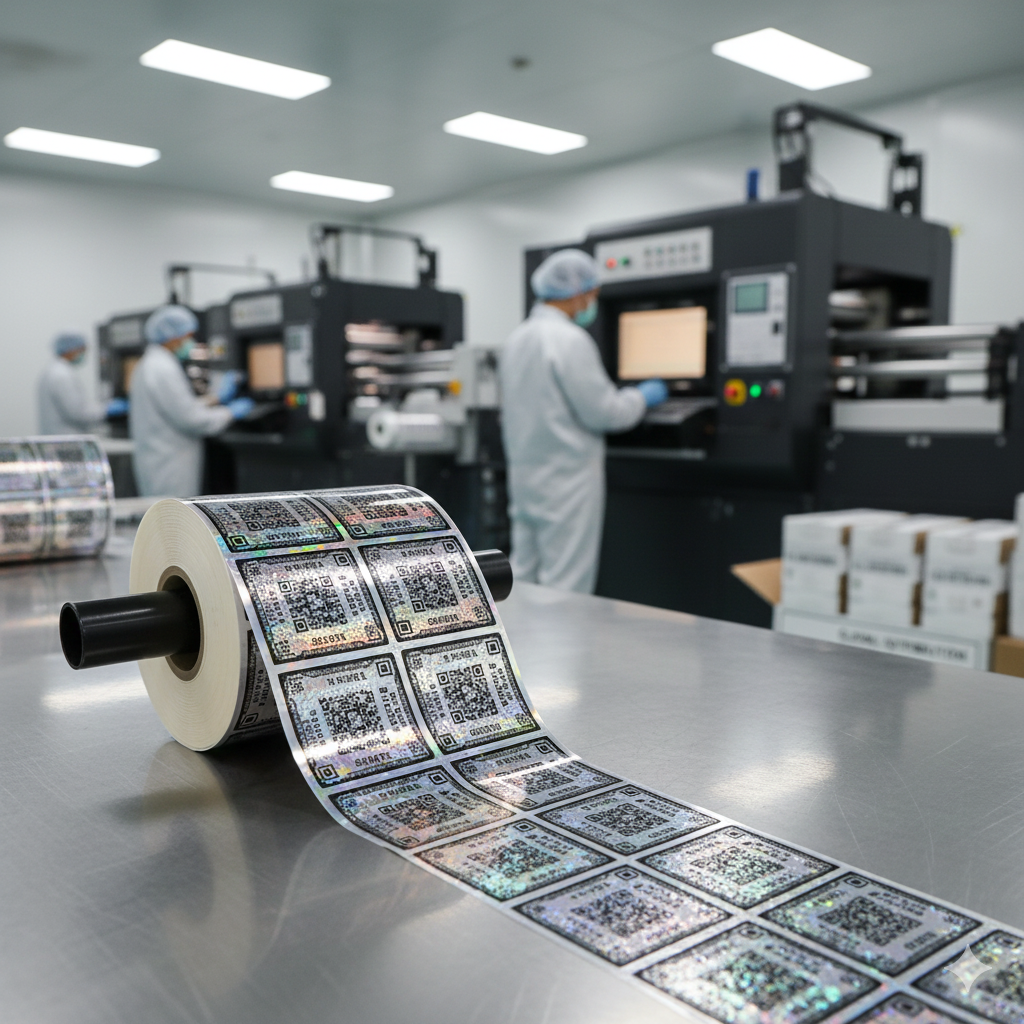

Design and Production Workflow

-

Market enforcement assessment

-

Inspection behavior analysis

-

Overt tamper logic design

-

Material and adhesive calibration

-

Handling and misuse simulation

-

Batch consistency control

All production follows ISO 14298 secure printing management systems, ensuring reliability even where oversight is limited.

Why Brands Choose Huaxin for High-Risk, Low-Enforcement Markets

Huaxin supports brands operating where inspection gaps create real exposure.

Key advantages include:

-

Security labels that communicate tampering instantly

-

Designs that do not rely on tools or training

-

Adhesives engineered to prevent reuse

-

Stable performance under harsh logistics

-

OEM experience in emerging and frontier markets

According to McKinsey’s 2024 Global Illicit Trade Report, counterfeit activity concentrates in regions with limited enforcement—making overt, behavior-driven security essential.

FAQ — Questions Common in Weak-Inspection Markets

Do we still need covert features?

They can be added, but overt security must work independently.

Will rough handling trigger false tamper signals?

No. Durability and tamper activation are engineered separately.

Can these labels work without digital systems?

Yes. Physical verification is the foundation.

Are they compatible with automated application?

Yes. Roll formats support industrial lines.

In Weak Inspection Markets, Ambiguity Is the Enemy

Where enforcement is inconsistent, counterfeiters rely on doubt.

A well-designed security label removes that doubt by making tampering obvious, immediate, and impossible to explain away.

With Huaxin, security labels are engineered to protect products even when inspection infrastructure is limited—because that is where protection matters most.

To discuss security label solutions for weak-inspection markets, visit the

Huaxin homepage or contact us here.