The Challenge: Maintaining Security in Harsh Logistics Conditions

Food safety and anti-counterfeit protection must endure a variety of difficult conditions, especially during logistics and packaging.

Two critical conditions where food packaging and labeling face the most stress are cold chain logistics (storage and transport in freezing conditions) and heat sealing (which can cause adhesive failure if not properly managed).

In these environments, labels must stay intact, readable, and secure despite temperature extremes and handling pressures. Security labels need to combine Barcode Anti-Counterfeiting Technology and durable materials to protect the product throughout its journey.

Why Cold Chain and Heat Sealing are Critical Challenges for Food Security Labels

Food products that require cold chain logistics include:

-

Frozen foods

-

Dairy products

-

Meat and seafood

-

Pharmaceuticals

In contrast, heat sealing is a crucial process for many food packaging systems, especially in products like:

-

Vacuum-sealed meats

-

Canned foods

-

Ready-to-eat meals

In both cases, if the labels fail, it opens the door for counterfeiters to repackage or illegally modify the products. This is why tamper-evident labels with advanced Barcode Anti-Counterfeiting Technology are designed to resist both environmental extremes while offering clear security features.

What Makes a Food-Safe Anti-Counterfeiting Label That Survives Harsh Conditions

A food-safe anti-counterfeiting label must meet several key performance requirements to withstand cold chain and heat sealing processes without compromising on security. Below are the critical factors:

1. Material Selection: Durable and Compliant

Choosing the right materials is crucial for ensuring that labels can withstand both cold and heat. Huaxin uses:

-

Cold-resistant films: Materials that don’t contract or become brittle under low temperatures.

-

Heat-resistant substrates: Films and papers that maintain integrity during heat sealing processes.

-

Food-safe adhesives: Designed to bond securely to various food packaging surfaces, from glass jars to plastic containers, without contaminating the product.

-

Low-migration ink systems: These ensure that the ink does not migrate to the food, complying with global food safety standards.

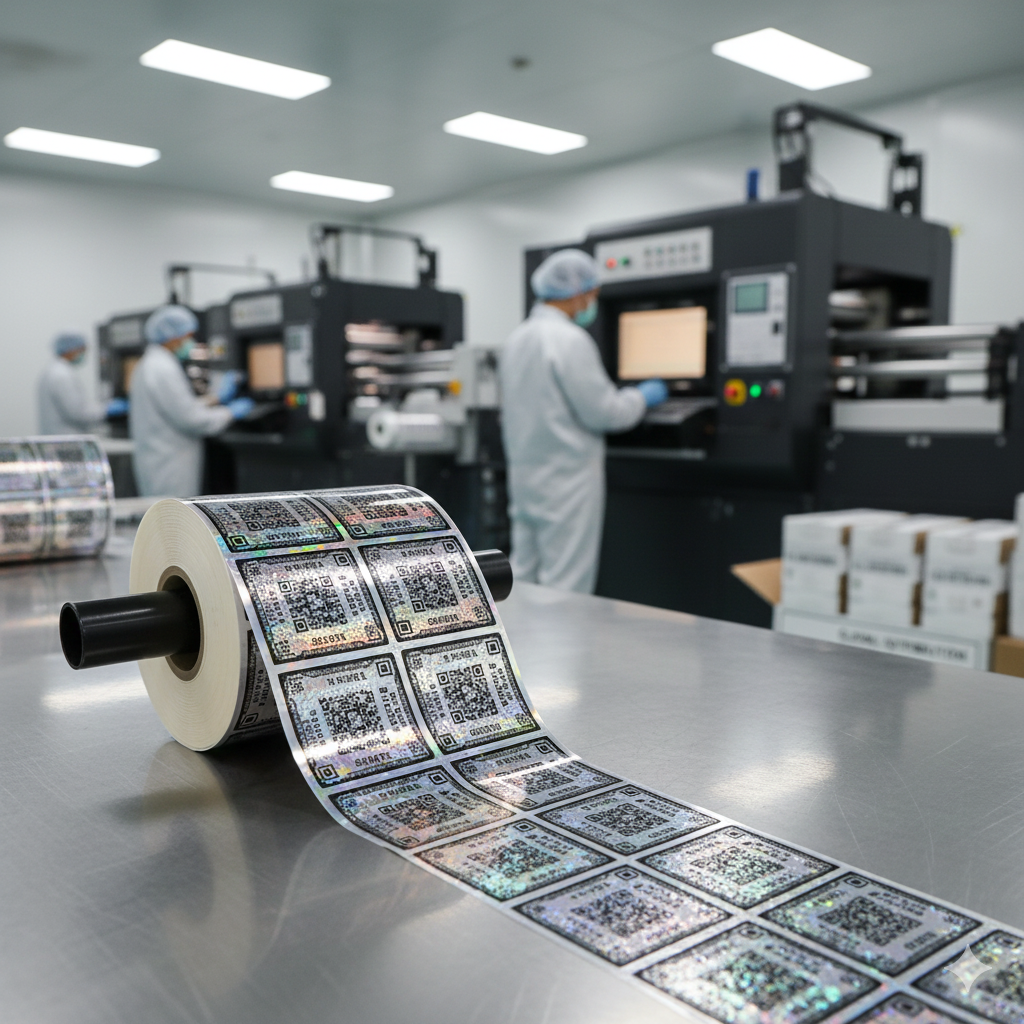

2. Barcode Anti-Counterfeiting Technology for Tracking

Huaxin integrates Barcode Anti-Counterfeiting Technology into the label design, which allows for:

-

Instant authentication: Barcode systems enable quick scanning and verification by inspectors, without needing specialized equipment.

-

Track and trace: Serialized barcodes help trace products back through the supply chain to verify origin, batch, and distribution history.

-

Tamper evidence: When the label is lifted, void patterns or other security features embedded into the barcode are revealed, showing visible evidence of tampering.

This technology enhances traceability, allowing for faster response to counterfeit incidents or recalls.

3. Adhesive Engineering to Withstand Temperature Shifts

Adhesion is one of the most critical factors for ensuring label durability during cold chain and heat sealing. Huaxin’s labels are engineered with adhesives that:

-

Maintain a firm bond under freezing conditions

-

Resist peeling during storage and handling

-

Activate tamper evidence only when deliberately removed

These adhesives ensure that the labels remain securely in place during both cold storage and heat sealing, making it nearly impossible to remove and reuse the labels without leaving evidence of tampering.

4. Printing Techniques That Ensure Clarity and Durability

Printing technologies must endure cold chain and heat sealing conditions without fading, smearing, or becoming illegible. Huaxin uses:

-

UV printing: To produce high-contrast, tamper-evident prints that are readable even under UV light.

-

Microscopic text: Printed for additional security, only visible under magnification, making it almost impossible for counterfeiters to replicate.

-

Durable inks: These inks are resistant to both freezing and high temperatures, ensuring long-lasting readability.

Common Issues with Labels in Cold Chain and Heat Sealing

Many labels fail in cold chain logistics and heat sealing processes due to poorly selected materials or adhesives.

| Issue | Standard Labels | Huaxin Food-Safe Labels |

|---|---|---|

| Adhesive failure | Peels in cold or heat | Bonds securely under extreme conditions |

| Fading text or graphics | Easily smeared in transport | Durable ink that survives cold and heat |

| Tamper evidence reliability | Subtle or easily erased | Irreversible damage when tampered |

| Compatibility with sealing | Doesn’t survive heat sealing | Engineered for high-pressure heat sealing |

| Cold chain durability | Becomes brittle | Cold-resistant, flexible materials |

Frequently Asked Questions

1. Can food-safe anti-counterfeiting labels work in freezing temperatures?

Yes. Huaxin uses cold-resistant materials that maintain integrity and readability in freezing conditions.

2. Will the adhesive hold up during heat sealing?

Yes. Huaxin’s labels are specifically designed to resist heat sealing without compromising adhesion or security.

3. How does Barcode Anti-Counterfeiting Technology enhance security?

It allows for instant, real-time authentication, traceability, and tamper detection, ensuring each product's authenticity throughout its lifecycle.

The Final Word: Food-Safe Labels That Endure Without Compromising Protection

For food products moving through complex supply chains, tamper-evident labels must withstand both cold chain and heat sealing. Labels that fail at any stage expose the product to risk, opening the door for counterfeiting and fraud.

With Huaxin, you get food-safe anti-counterfeiting labels engineered to withstand extreme conditions without sacrificing security or compliance. Whether it's cold storage, transport, or packaging processes, our labels remain intact, readable, and highly secure.

To discuss custom food-safe anti-counterfeiting labels or request technical specifications, visit the

Huaxin homepage or contact us here.