Anti-Counterfeit Labels for Products Most Likely to Be Reused or Refilled

Reuse and Refilling Are the Quietest Forms of Counterfeiting

Not all counterfeit products look fake.

Some look perfectly legitimate—because they once were.

Refilling genuine bottles, reusing original packaging, or transferring authentic labels onto substitute products is one of the most effective counterfeit methods in the market today. It bypasses visual inspection and exploits weak label behavior rather than weak branding.

For these products, the role of an anti-counterfeit label is clear:

it must make reuse and refilling physically impossible to hide.

Which Products Face the Highest Reuse and Refill Risk

From enforcement cases and brand investigations, reuse-driven counterfeiting concentrates around products that share three characteristics:

-

High turnover or repeat purchase demand

-

Containers that can be opened and resealed

-

Labels that can be removed without damage

Typical high-risk categories include:

-

Alcoholic beverages and spirits

-

Cosmetics and personal care liquids

-

Pharmaceuticals and supplements

-

Automotive fluids and chemicals

-

Cleaning agents and household liquids

In these categories, a label that behaves like a normal sticker becomes a liability.

Why Standard Labels Enable Reuse-Based Counterfeiting

Many brands underestimate how easily genuine labels are recycled.

Common failure patterns include:

-

Clean peel-off without visible damage

-

Adhesives that re-bond after removal

-

Labels that stretch and recover shape

-

Minimal residue left on the container

Once a label can be reused, counterfeiters no longer need to copy anything. They simply repurpose what already exists.

What Anti-Counterfeit Labels Must Do in Reuse-Prone Products

1. Enforce Irreversible Tamper Evidence

For refill protection, tamper evidence must be destructive, not symbolic.

Huaxin engineers tamper behavior using:

-

VOID-transfer constructions that permanently expose hidden messages

-

Destructible substrates that fracture into fibers

-

Partial-transfer layers that split when lifted

-

Seal-style labels that bridge closures and containers

Once disturbed, the label cannot return to a valid appearance.

This removes all room for debate during inspection.

2. Separate Durability From Tamper Activation

One common mistake is assuming fragile labels improve security.

They do not.

Anti-counterfeit labels must remain intact during transport, storage, and handling—and fail only under deliberate removal.

Huaxin achieves this by:

-

Calibrating adhesive strength to resist vibration and friction

-

Designing tamper mechanisms that activate only under peel force

-

Preventing accidental edge lift during logistics

The result is stability without false alarms.

3. Prevent Label Transfer Between Containers

Reuse often involves moving an original label from one container to another.

Huaxin prevents this by ensuring:

-

Visible residue remains on the original container

-

Label layers split during removal

-

Tamper patterns remain readable even after partial lift

Once removed, the label becomes unusable—by design.

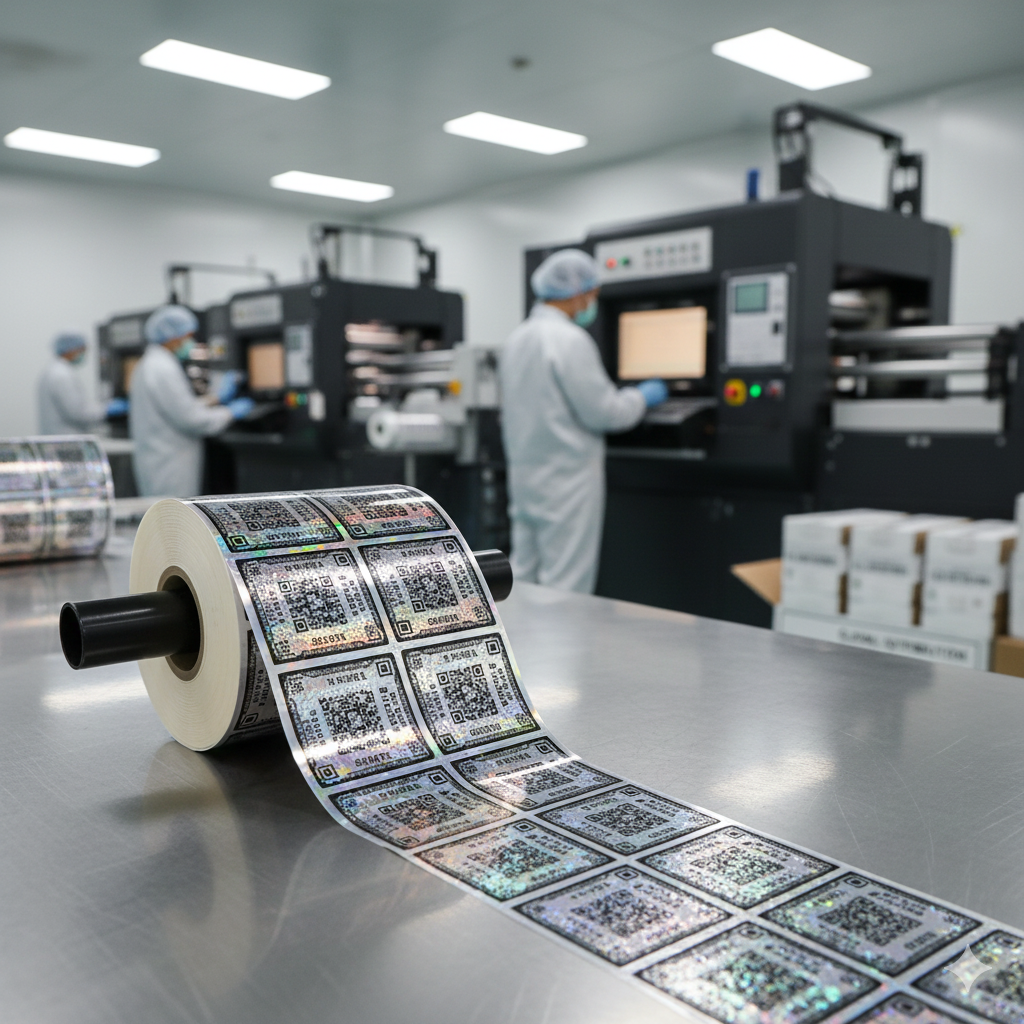

4. Add Identity Control Through Serialization

Physical damage alone may not stop organized reuse schemes.

Huaxin integrates serialization so each label carries a unique identity:

-

Individual serial numbers

-

Batch or date codes

-

Optional QR or data matrix formats

Serialization allows brands and inspectors to detect duplication, repeated use, or circulation outside intended channels.

Why Reuse-Resistant Labels Change Inspection Outcomes

In refill-prone markets, inspection often relies on speed, not lab tools.

A well-designed anti-counterfeit label ensures that:

-

Tampering is visible without explanation

-

Damage patterns are consistent and recognizable

-

Authentic labels cannot be “repaired”

-

Inspectors can make decisions quickly

This clarity reduces disputes and enforcement delays.

How Huaxin Designs Labels for Reuse and Refill Risk

Huaxin treats reuse prevention as a system-level problem, not a single feature.

Design and Production Workflow

-

Reuse-risk assessment by product and container type

-

Tamper behavior selection based on opening method

-

Material and adhesive calibration for real surfaces

-

Security printing and optional serialization

-

Handling and tamper stress testing

-

Batch traceability and documentation

All production follows ISO 14298 secure printing management systems, ensuring repeatable behavior at scale.

Why Brands Choose Huaxin for Refill-Prone Products

Huaxin supports brands where reuse risk directly impacts revenue and reputation.

Key advantages include:

-

Tamper evidence designed for real refill scenarios

-

Adhesives that expose removal clearly

-

Stable serialization for identity tracking

-

Security features readable under field inspection

-

OEM manufacturing experience for global markets

Industry studies, including McKinsey’s 2024 Global Illicit Trade Report, identify refilling and reuse as dominant counterfeit methods in consumable categories—underscoring the need for engineered label behavior.

FAQ — Practical Questions Brands Ask

Can anti-counterfeit labels stop refilling completely?

They make refilling visible and commercially unviable by exposing tampering.

Will labels survive transport without triggering false damage?

Yes. Durability and tamper activation are engineered separately.

Can reuse-resistant labels include QR codes?

Yes. Physical and digital verification can be combined.

Are labels compatible with automated filling lines?

Yes. Machine-ready roll formats are supported.

Reuse-Proof Labels Protect More Than Packaging

For products most likely to be reused or refilled, security depends on behavior—not appearance.

An effective anti-counterfeit label removes ambiguity, exposes interference instantly, and ensures that once a container is opened, authenticity cannot be faked again.

With Huaxin, anti-counterfeit labels are engineered to stop reuse where it actually happens—at the container, at the label, and at the moment of removal.

To discuss reuse-resistant anti-counterfeit label solutions, visit the

Huaxin homepage or contact us here.